Autoclave Control Systems

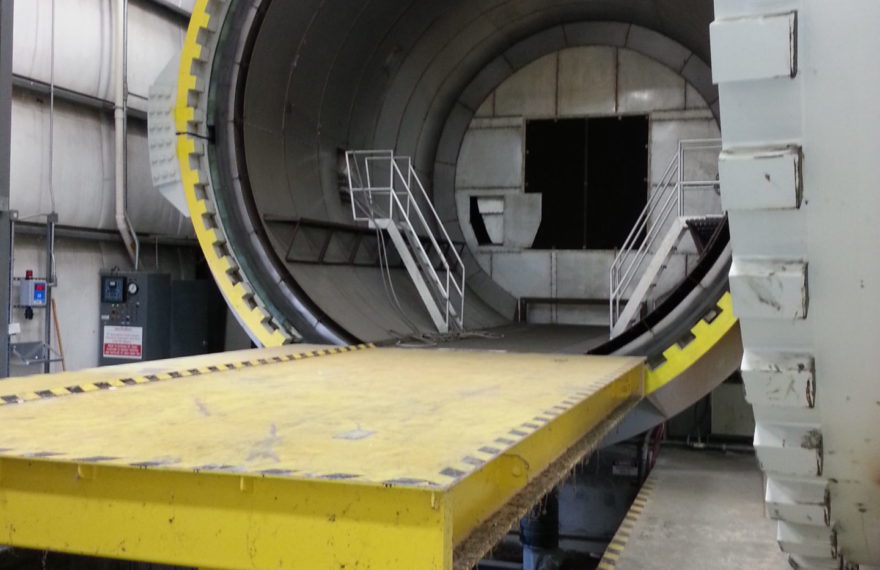

CompuDAS have designed, innovated, built, installed and supported Autoclave Control Systems for Process Control, Monitoring and Data Acquisition for autoclaves all over the globe for over 50 years.

July 22, 2015

Aerospace • Autoclave Control Systems • Automotive • Composites • Engineering

More Information

· Call: +1 360 427 1418

· Download Documents

· Online Inquiry

CompuDAS have designed, innovated, built, installed and supported Autoclave Control Systems for Process Control, Monitoring and Data Acquisition for autoclaves all over the world for over 50 years for the world’s’ biggest manufacturers and smallest custom clients.

Autoclaves are a critical step in many manufacturing processes. Craftsman or large-scale industrial, the exact application of controlled heat and pressure to cure materials is a one way process that you need to get right time and time and time again to produce the consistent, reliable, high quality products that your customers require.

If you need to compete on quality, price or turnaround, then you just can’t afford to lose a single batch.

Whatever your ‘recipe’, whether you seek precision control of the composite curing a custom sailboat spar, a highly-specialized aerospace component, or the batch sterilization of medical implements, you can count on CompuDAS Control Systems for the right result.

Why install or upgrade to a CompuDAS Autoclave Control System?

Our advanced Autoclave Controls deliver Full Recipe control, Vacuum & Variable Vacuum Control, and Complete Process control for all types of autoclave. We can retrofit CompuDAS control systems on 50 year old autoclaves or install them on the latest in autoclave technology fresh from the factory.

We provide custom control solutions for electric heated autoclaves, gas heated autoclaves, steam heated autoclaves – we have even seen an autoclave heated with hot oil!

I’ve got a unique autoclave setup, how will a CompuDAS Autoclave Control System work for me?

Because of the huge variety in the field, every upgrade project is different. Each installation requires a certain amount of customization and improvisation, but a new CompuDAS control system will enable almost any autoclave or oven to meet the most stringent process requirements in the world.

How do I control my industrial autoclave process?

CompuDAS Autoclave Control Systems manage and automate all aspects of the Autoclave curing process. The autoclave Control System can be operated from familiar user-friendly Windows based interface installed on any compatible PC.

Each segment can be programmed for ramp times, temperatures, pressure or vacuum levels, and other parameters. Thermocouples and other sensors can be labeled in the job setup to correspond to specific parts or locations in the vessel. Segments can be triggered by either time or process conditions. For example, the start of a soak time might be delayed until a lagging thermocouple reaches a required temperature. Conditions to be monitored and recorded are also specified as part of the recipe.

Reliable & Redundant

Unlike many other control systems CompuDAS do not rely on an unstable PC to run the recipe. Instead the PC recipe is downloaded to the Control Unit’s own on board computer for every run. Should the PC crash or network stall during a cure, your cycle and batch are safe with the CompuDAS Control System directly managing the process – and the data will all be there once the cure is complete!

What are the costs to install or upgrade to an Autoclave Control System?

There are costs to installing, retrofitting or upgrading an autoclave Control System. But it’s probably a lot less than you think. For most clients, scrapping a single batch of high-performance composites can cost nearly as much or more than the price of a new control system.

Any control system failure, or a mistake as simple as forgetting to turn on a chart recorder, can render an entire batch useless. The benefits of improved process control and monitoring are well worth the cost of upgrading.

Studies have demonstrated energy savings of up to 30% and faster processing times by a process we call “superheating” the autoclave, bringing lagging parts to temperature faster. Automatic monitoring of this process allows ramp times to be reduced while ensuring that no parts overheat.

Upgrading an existing autoclave or oven costs far less than replacing it. Less down time and workplace disruption are required for installation. Keeping the same equipment usually means that floor plans do not have to change, and few modifications are needed for electrical or gas supplies, ventilation, or other peripherals.

When multiple autoclaves and ovens are on site, control system upgrades offer the possibility of standardizing the operating system so that all units use the same software. When all of the control systems work the same way, less training is required, and operators can move more readily from one station to another. The procedure for setting up recipes is consistent, as are process records and reports, which simplifies engineering and quality control.

Finally, modern control systems can automate the entire process of curing composites. Once parts are in place and instrumentation is mounted, simply select the correct recipe on the computer and push the start button. The control system takes care of the rest, from start to finish . When you install a Control System for your autoclaves, you eliminate the need for continuous process monitoring, freeing operators to work on other tasks

Can a CompuDAS Autoclave Control system help me with process compliance for my composite bonding autoclave, curing autoclave, aerospace autoclave, industrial autoclave, automotive autoclaves – processes that produce life critical materials?

This razor-precise continuous monitoring of all measurement channels and parameters in the selected recipe ensures complete and consistent cures with each job. Data acquisition means that you can demonstrate the full process each batch was subjected and demonstrate compliance with any ISO or other industry standard, customer requirements, or regulations.

In fact, with CompuDAS Autoclave Controls, you can access a full monitoring suite. The Control System will also provide full data acquisition, giving you configurable graphs and tables on the precise time, temperature, pressure curves and other vital information about each autoclave cycle. You need to know the exact parameters of each batch, and our Autoclave Control Systems put that information at your fingertips.

Who uses CompuDAS Autoclave Control Systems?

Our Critical Process Control systems have been installed onto many autoclave applications worldwide. Large or small, our highly customizable hardware and software has been developed specifically for composite curing. In our 40+ years in the industry we have found that many of our customer specific needs vary to some degree. Our software can easily be modified to meet your requirements.

We can also adapt our Autoclave Control Systems to other industries needs for pressure vessel controls and data acquisition.

We’ve installed curing oven controls, cpc thermal processing controls, composite bonding autoclave controls for a wide range of industries. Please ask us for references that reflect your industry, process, and product needs.

CompuDAS Control Products

What sort of autoclaves do CompuDAS Autoclave Control Systems monitor and control?

- All General Industrial autoclaves

- Composites autoclaves

- Glass laminating autoclaves

- Wood autoclaves

- Vulcanizer autoclaves

- Dewaxing autoclaves

- Nuclear autoclaves

- Autoclaved aerated concrete (AAC) autoclaves

- Aerospace autoclaves

- Glass autoclavess

- Ballistics autoclave

- Concrete autoclaves

- Automotive autoclaves

- Investment casting autoclaves

- Rubber vulcanizing autoclaves

- Rubber products autoclaves

- Pressure treated wood autoclaves

- Sterilization autoclaves

- Manufacturing autoclaves

- Composites curing autoclaves

- Structural adhesive bonding autoclaves

- Lost-wax casting autoclaves

- Curing autoclaves

- Waste products autoclaves

What 10 questions should I ask when choosing Autoclave Control Systems?

What are the capabilities of the autoclave control systems? Can it follow a pre-programmed recipe? Can it control soak times by monitoring a leading or lagging thermocouple or average of all thermocouples? Does it record process data automatically? Can it control vacuum?

Yes it can!

Who will install the control system? Will it be done by the manufacturer or by a subcontractor?

We analyze, plan, review, and install all our custom Autoclave Control Systems ourselves. You will know whom you are dealing with from beginning to end, and you will know how to get ahold of us is if there are questions. For the life of your system.

Can the control system be configured to meet my needs? Every upgrade installation has its challenges. Customization and a certain amount of improvisation are often needed to match the control system to the application. How much will the installer do to make the control system work optimally with your equipment?

We will make certain that your Control System is completely customized to fit your needs. We have worked with highly unique situations, and have even installed Control Systems on a 50-year old autoclave that the manufacturer could not afford to replace without setting off a prohibitively expensive avalanche of building upgrades. We’ll be there during planning and installation, and we’ll be there after to ensure that the Autoclave Controls function as intended.

How are recipes created? Be sure to get a demonstration of the software. Pay attention to how usable the software is, how much effort is required to input a recipe, and how much training will be required.

CompuDAS Control System Recipes allows you to create recipes using menus on your PC (a backup PC for fail-safe is recommended Delete–). Each segment can be programmed for ramp times, temperatures, pressure or vacuum levels, and other parameters. Thermocouples and other sensors can be labeled in the recipe to correspond to specific parts or locations in the vessel. Segments can be triggered by either time or process conditions. Conditions to be monitored and recorded are also specified as part of the recipe.

How is the installation protected from power failures, network outages, or PC crashes?

The control system should be able to continue controlling the process and collecting data even if communication with the PC is lost. Ask what protections are built into the system.

What information is available to the operator during the cure cycle? How are process parameters displayed? How are alarms displayed? Can recipe values be overridden manually if necessary? Can the process be monitored remotely?

CompuDAS Autoclave Control Systems provide you the with continuous monitoring of any parameters of interest in your process.

What types of reports can be created, and how are they generated? Make sure that the software is configured for easy access to the reports you need. Are they accessible from other locations, or only on the controlling PC? How difficult is it to find and access data from past batches?

We’ve put the ability to customize reports, graphs, table, and data and store, send, and share it according to your needs at your fingertips.

How is data protected from tampering?

If proof is required that composite materials were cured according to a specific recipe, you need to be able to show that the data collected during the process was not modified in any way. Find out what safeguards are built into the software to prevent changes. Our control systems are designed with this need in mind.

How is data protected against loss?

Customers using materials in demanding applications often require cure data to be kept for the life of the part. Even if it is not a requirement, having an archive of this data can protect you from liability. Make sure that records are backed up in a secure, off-site location. Our Control Systems are designed to be configurable for multiple backups and real-time transfer to off-site storage.

What happens after support expires? Do you have to purchase a software upgrade or support contract? How much will that cost?

We stand by our products and our prices for support, service, and upgrades are never hidden. Though some unique circumstance might require custom solutions, we’ll never catch you out with hidden costs.

Products

- Critical Process Controls

- Compare Products

- Critical Process Control Model CPC-16EX

- Critical Process Control Model CPC-8

- Critical Process Control Model CPM-8

- Critical Process Monitor CPM-16

- Critical Process Monitor CPM-16EX

- The Sentinel

- Uniformity Calibrator UC-45

- Variable Vacuum Upgrade Kit

- Download Factsheets

Applications

News

Popular

Sorry. No data so far.

Contact

CompuDAS Controls, LLC

1350 E Shelton Springs Rd

Shelton, WA 98584

United States

Main: +1 360 427-1418

Email Sales/Support